3D Part Imaging /Non-Contact Laser Scanning

For Use in Reverse Engineering

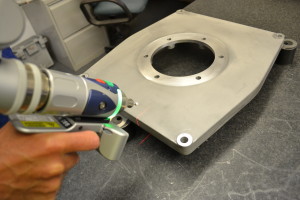

Through the use of coordinate measuring machines (CMMs) such as the FaroArm we at Wadelynn Geospatial possess the knowledge and expertise to provide you high quality and highly accurate 3D Point Clouds, Models, and As-built Drawings that can be used in Reverse Engineering of your part.

By adding a scanner to the CMM we can accomplish unparalleled non-contact 3D scanning capabilities for detailed measurement of surface form, making our solutions the perfect combination of a contact and non-contact portable CMM.

Our equipment digitally re-creates your part.

Our Process

We begin by assessing your needs. We are flexible problem solvers and will tailor a solution to fit your need. On most part imaging projects, we will elect to use one of our portable CMMs. A CMM allows manufacturers easy verification of product quality by performing 3D inspections, tool certifications, CAD comparison, dimensional analysis, reverse engineering, and more.

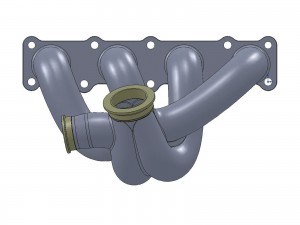

Once we have scanned the part our 3D modeling specialists will begin working with the point cloud to create a 3D Solid Model with features using Geomagic Design X. The resulting model(s) can then be imported into nearly any CAD software package such as AutoCad, Solidworks, Inventor, etc.

Models can be used to generate as-built drawings or fabricate replacement parts. 3D printing/machining solutions will also be discussed dependent on your need and part materials.

Quality over quantity – Quality is very important to us. Our QC process will be outlined prior to beginning any project. We will work with you to develop a system that is effective and efficient. We often merge our QC plan with a client’s internal procedures to provide you with the assurance that you are receiving the best product possible.

Things we consider in the planning process

- Part size

- Reflectivity of the part

- Accessibility to the part(s) – scanned on-site? – while in service?

- Desired Deliverables

- Project Schedule

Benefits of 3D Digitizing

- Highly accurate results and thorough quality assurance

- Measure and Model uniquely shaped parts

- Easily create replica or manufacturing molds

- Save $$ – fast data acquisition / modeling gets you from concept to manufacturing quickly

- Digital documentation of your parts in case of failure